Materials selection

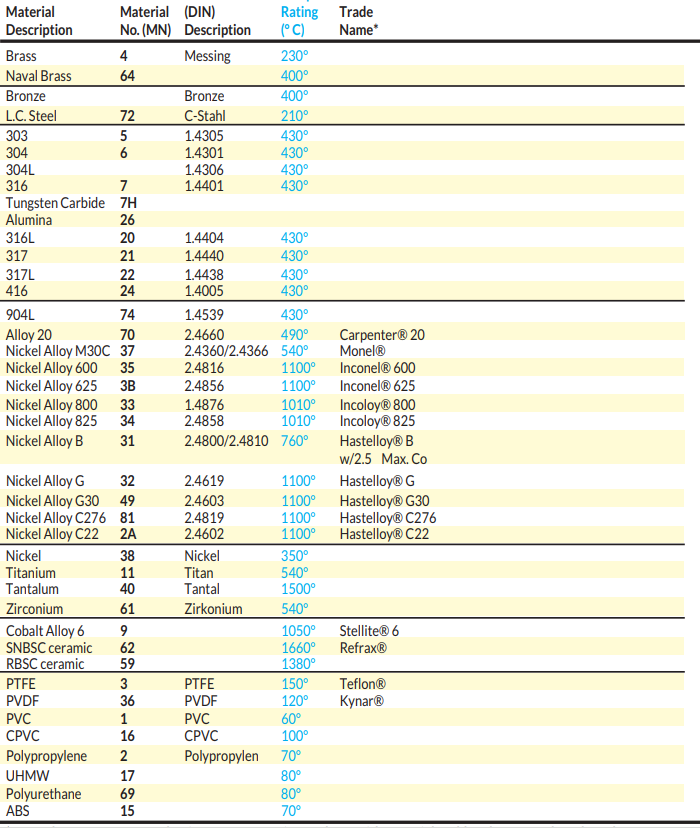

Many factors need to be considered when selecting the appropriate material of manufacture for spray nozzles. SNP offer nozzles in literally hundreds of different materials. The chart below shows 40 of the most popular materials and their operating temperature rating.

Melting or softening of material establishes maximum temperature limits. However, these temperature limits must be reduced when corrosion, oxidation, or chemical attack are also present. See column in blue for general temperature limits for various materials.

Other factors to consider

Corrosion

Plastics offer superior corrosion resistance at relatively low cost, but can only be used in low-temperature applications. In general, metals can be ranked in the following order of corrosion resistance (from lowest to highest): cast iron, brass, stainless steels, nickel-based alloys, refractory metals and precious metals. Ceramics have excellent corrosion resistance except in very high pH environments.

Chemical attack

There are few general guidelines to this complex subject, but the material used for piping may provide a useful indicator of a suitable nozzle material. If the environment of your application is known to contain substances which may attack the spray nozzle, contact SNP applications engineers for advice.

Abrasion

Hardened stainless steel, Cobalt Alloy 6, tungsten carbide, and ceramics are commonly used in applications where abrasive fluids are sprayed.

Cost

There are exceptions, but materials can generally be ranked in the following order in terms of cost (from lowest to highest): brass, cast iron, plastics, stainless steels, cobalt-base alloys, nickel-base alloys, ceramics, refractory metals and precious metals.